Call Us

08045813929

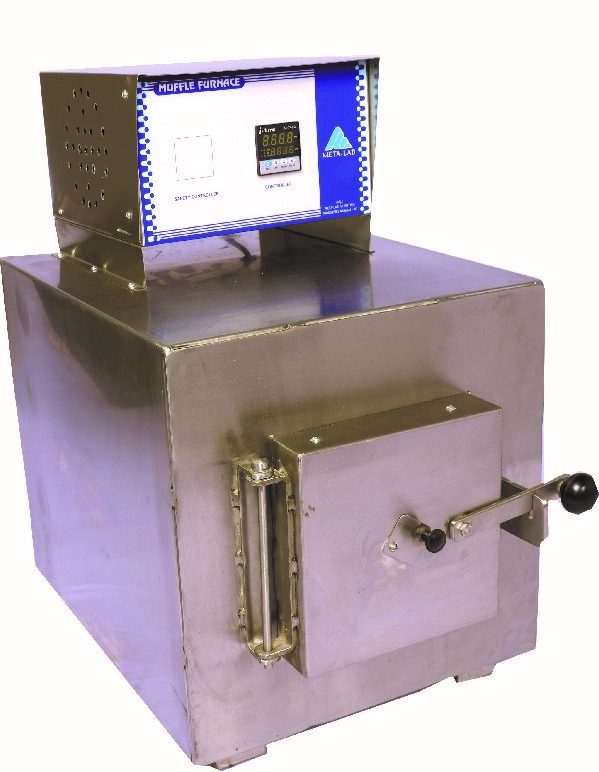

Rectangular Muffle Furnace

Product Details:

- Condition New

- Type Furnace

- Usage Muffle Furnace

- Size Sizes Available

- Product Type Rectangular Muffle Furnace

- Voltage 220 Volt (v)

- Color White

- Click to view more

X

Rectangular Muffle Furnace Price And Quantity

- 1 Unit

Rectangular Muffle Furnace Product Specifications

- Rectangular Muffle Furnace

- White

- 220 Volt (v)

- Furnace

- Muffle Furnace

- Industrial

- Sizes Available

- New

Rectangular Muffle Furnace Trade Information

- 100 Unit Per Month

- 7 Days

Product Description

- LIGHT WEIGHT CERAMIC FIBRE WOOL INSULATION.

- COMPLETELY MADE OF STAINLESS STEEL 304.

- BODY IS MADE OF THICK GUAGE SS MATT FINISHED.

- INNER POT IS MADE OF CERAMIC MUFFLE.

- DOOR INSULATION BRICKS HFK MAITHAN.

- HEATING ELEMENTS MADE OF KANTHAL A1 WIRE.

- HEATING ELEMENTS ARE WOUNDED AROUND THE MUFFLE.

- HEATING ELEMENTS ARE COVERED WITH CERAMIC BLANKETS OF 96 DENSITY.

- MICROPROCESSOR BASED AUTO TUNE PID DIGITAL TEMPERATURE CONTROLLER.

- K TYPE CR AL THERMOCOUPLE.

- TEMPERATURE RANGE : UP TO 1120

- OPERATING TEMPERATURE : UP TO 1150°C

- TEMPERATURE RESOLUTION : C

- CONTROL ACCURACY : +-1% OF FSD

Wide Range of Sizes Available

The Rectangular Muffle Furnace is offered in various sizes to suit different experimental and industrial requirements. Whether you need a compact unit for small-scale laboratory work or a larger furnace for bulk material testing, theres an option to meet your needs. Each size maintains consistent heating efficiency and safety features.

User-Friendly Operation

Designed for effortless use in laboratory and industrial environments, this muffle furnace features intuitive controls and sturdy construction. Its straightforward setup and reliable voltage compatibility ensure minimal training is required for operation, making it suitable for routine applications and specialized processes alike.

FAQs of Rectangular Muffle Furnace:

Q: How is the Rectangular Muffle Furnace typically used in laboratories and industrial settings?

A: The Rectangular Muffle Furnace is primarily employed for high-temperature applications such as ashing, material analysis, heat treatment, and sample preparation. Laboratories often use it for precise thermal processing, while industries utilize it for quality control and production testing.Q: What sizes of the Rectangular Muffle Furnace are available, and how do I choose the right one?

A: A variety of sizes are available, ranging from compact models for routine lab tasks to larger units for industrial-scale operations. Selecting the appropriate size depends on the volume of material you need to process and the specific nature of your applications.Q: When should I consider using a muffle furnace over other types of furnaces?

A: You should opt for a muffle furnace when your process requires isolated heating, excellent temperature uniformity, and minimal contamination of samples. It is ideal for tasks that demand precise control or clean environments, such as analytical testing and heat treatments.Q: Where can I purchase the Rectangular Muffle Furnace in India?

A: The furnace is available throughout India via multiple channels, including distributors, exporters, manufacturers, suppliers, and traders. You can contact verified dealers for technical specifications, pricing details, and availability.Q: What is the process for installing and operating the Rectangular Muffle Furnace?

A: Installation is straightforwardposition the furnace on a stable, heat-resistant surface, connect it to a 220 Volt power outlet, and follow the user manual to calibrate temperature settings. Regular maintenance includes cleaning the chamber and verifying electrical connections to ensure safe, efficient use.Q: What are the main benefits of using this muffle furnace?

A: Key advantages include reliable temperature control, versatile sizing options, energy efficiency, and durable construction. These features lead to precise processing outcomes, reduced contamination risk, and long operational life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese